The engineering company Ghenova has developed, through an R&D&I project co-financed by CTA (Technological Corporation of Andalusia) and in which the University of Seville participates, an innovative technology to detect, in an autonomous and non-intrusive way, the point of ripening of the avocado so that it can reach the point of sale at the optimum moment for its consumption.

The CEO of Ghenova, Francisco Cuervas, affirms that “thanks to the support of CTA, Ghenova has not only been able to develop an innovative technology, but has been able to do so in Andalusia and for a sector that demands high technological innovation to remain efficient, sustainable and competitive, such as the primary sector”. Cuervas valued CTA’s R&D&I incentive program for the aid provided for investment in research, the dissemination of results and the study and development of patents on the same.

Finally, Francisco Cuervas also highlights the decisive collaboration of “the important Malaga cooperative Trops in the project, contributing important knowledge in the field of application, and serving as prescribers of a technology that in 2024 will have become a product”. Based in Velez-Malaga (Malaga), the Trops cooperative brings together more than 3,000 avocado and mango growers and its production area is concentrated in the Axarquia region of Malaga and the tropical coast of Granada, along the coast of Valencia, the Portuguese Algarve, and as far as South America (Peru and Chile).

For her part, the technical manager of the Aerospace and Production Processes sector, Silvia de los Santos, affirms that the ARPODES project is “an important milestone in the use of robotics and artificial intelligence (AI) in a particularly relevant sector in Andalusia, such as agri-food”.

The TEP 153 Robotics, Vision and Control research group of the University of Seville (US) has participated in the project, thus achieving the transfer of knowledge from the scientific-university field to business activity.

Controlling the exact moment

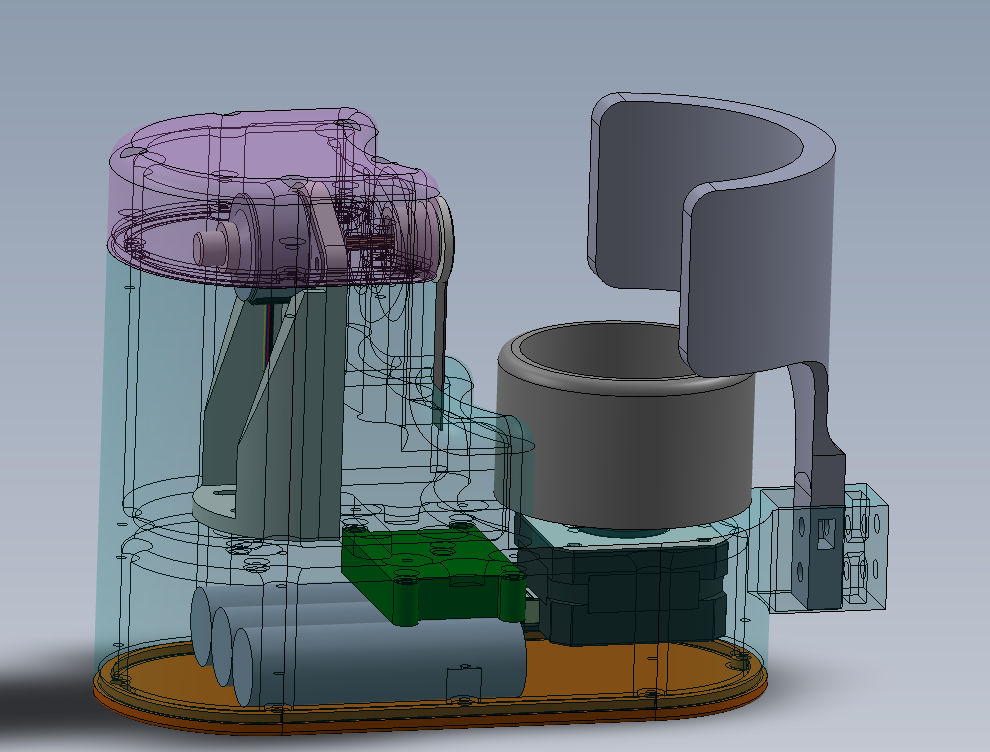

Ghenova has designed and developed a mechatronic system and its associated artificial intelligence (AI) to autonomously and non-intrusively monitor the ripening point of avocados.

In Andalusia, avocado production reaches 97,000 tons and represents about 70% of the production of all Europe. The great challenge of this production chain is to ensure that the product is in the greengrocers at the right point of ripeness to be consumed. This project aims to detect in real time the ripening point of the avocado and to adjust the time and conditions to the maximum so that it reaches the final consumer’s table in optimal conditions.

The system can be integrated into the production chain and adjust the conditions of the chamber in which the avocado is located according to a prediction of the ripening process of the fruit, in order to reach the required ripening point at the time of transport and/or sale.

Digitalization of the agri-food sector

Despite the high application of technology in the reception, sorting, packing and palletizing of avocados, the definition of the ripening point of the avocados in the ripening chambers and the establishment of the boundary conditions to ensure that this point is the desired one at the time of transport still has a strong human presence. Currently, this process is still done manually by expert personnel palpating the fruit and then adjusting the temperature, humidity and ventilation references of the chambers.

Ghenova’s proposed ripeness sensor mimics the farmer’s hand, measuring pressure on the avocado surface as a function of the displacement of a linear actuator. This technology, so far unpublished in the sector, would allow the evolution of the entire avocado industry, making it possible, for the first time and in a reliable way, to digitize the entire process of sizing during ripening, not only allowing to close the control loop, but also storing automatically all related data, being this an added value and useful for later application.